We Believe in Quality

An ISO:9001 : 2000 Certified Company

We Believe in Quality

An ISO:9001 : 2000 Certified Company

One of the most commonly used applications of acetylene gas is OXY-ACETYLENE WELDING, oxy welding, or gas welding.The oxy-acetylene welding process uses a combination of oxygen and acetylene gas in the approved ratio to provide a high temperature flame. In fact, the process uses fuel gases and oxygen to weld and cut metals, respectively.

The oxygen-acetylene welding was developed by French engineers Edmond Fouche and Charles Picardin 1903.Pure oxygen, instead of air, is employed to enhance the flame temperature to let localized melting of the work piece material (e.g. steel) in a room environment. The acetylene/oxygen flame burns at about 3,500 °C (6,330 °F).

|

| Oxy-acetylene welding process |

|

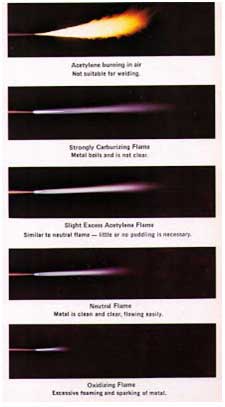

When the volume if oxygen gas is more than the volume of acetylene mixed into the torch. This flame is used for welding brass and is also used for cutting the metals.

When the volume of acetylene mixed is more than oxygen, carburizing flame is formed. This flame is used for welding nickel, monel etc.

It is known as balanced flame. Oxygen and acetylene gases are mixed in equal volumes. Neutral flame is used for normal welding of steel, cast iron etc,

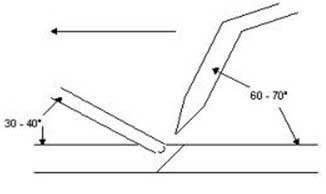

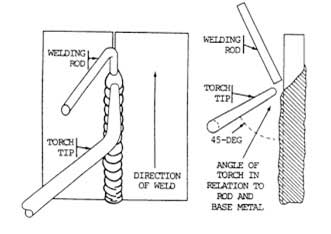

In this welding the tip of the torch is held at 600-700 to the plates. And the filler rod is inclined at 300-400 in opposite direction. In this method the plate edges are heated immediately after the molten metal. The torch tip and filler rod are moved slowly in the direction towards left.

|

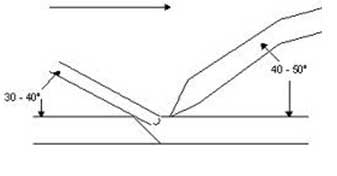

In right ward welding the torch is kept at 400-500 to the job to be welded. Torch is moved toward right. Right ward welding is done for heavy sections.

|

This is a method by which metal of any thickness can be welded. In case the thickness of the sheet is lesser then welding from one side will be sufficient but for thicker sheets welding should be done from both the sides. Preparation of edges to be weld is not required. In this case welding starts from bottom and moves till top and the welding blow pipe follows the filler rod. The inclination of the blow pipe is 30-80 degree whereas filler rod is inclined at an angle of 30.

|

|

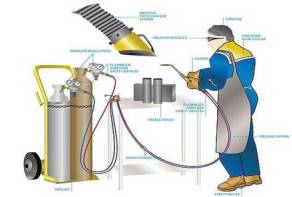

There is a number of equipment needed for the procedure, including:

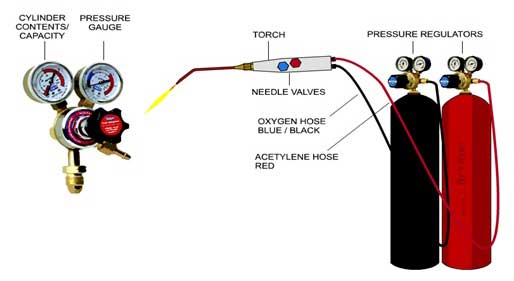

A welding torch is a vital device used to combine both the gases -fuel or acetylene and oxygen - to create a flame that is hot and strong enough to cut the metals. It has been designed and developed in a manner so that the operator can control both the shape of the flame and its intensity via a pair of valve knobs placed towards the end of the handle.These needle valves work to change the flow of oxygen and fuel as needed.

The hoses are specifically designed and developed for welding and cutting metals. The two hoses joined together and color-coded for visual identification. In addition,threaded connectors are handed to shun accidental mis-connection: oxygen is right-handed as usual, fuel gases use a left-handed thread.

The gas regulators are also vital equipment with the primary function to control gas pressure. It controls high pressure of the bottle-stored gas to the working pressure of the torch and maintains during welding process.The gas regulators have two separate gauges - a high pressure gauge works to determine remaining gas in the cylinder and a low pressure gauge to determine pressure of gas fed to the torch.

Note: Acetylene gas is filled in cylinders under a pressure of about 15 bar, while welding process is carried out with torch gas pressures typically up to 2 bar.

The welding torch head is used to weld metals. There are only one or two pipes going to the nozzle and no oxygen-blast trigger and two valve knobs at the bottom of the handle allowing the operator adjust the oxygen flow and fuel flow. It is also a one of the vital equipment.

Similar to a welding torch, a cutting torch head is used to cut materials. But the torch can be identified by the oxygen blow out trigger or lever. Once the desired temperature is attained, oxygen is supplied to the heated parts by pressing the "oxygen-blast trigger". The supplied oxygen reacts with the metal, and thus forming iron oxide and producing heat. This heat is used for the cutting process.

The chemicals which de-oxidises the metal surface and provides inert atmosphere around the molten metal are known as fluxes.

Function:

Fluxes are available as liquid, powder, paste and gas. Powder flux is sprinkled on the surfaces to be welded or the filler rod is dipped into the powder. Liquid and paste fluxes are sprayed on the surfaces to be welded. Gas fluxes are used to form inert atmosphere around the joint to be welded.

The rod which provides additional metal in completing the welding is known as filler. The composition of filler metal should be the same as that of the metal to be welded.

|

For different types of jobs, different tips are used. The size of the tip is specified by the outlet hole diameter. More than one hole is also provided in tips. The tip is screwed or fitted on the front end of the torch.

|

Gas flames produce high intensity light and heat rays, which are harmful to naked eyes. To protect the eyes from these rays, goggles are used. Goggles also protect the eyes from flying sparks.

|

For starting the flame, the spark should be given by the lighter. Match sticks should not be used, as there is risk of burning hands.

|

Fire extinguishers are used to prevent the fire that may break out by chance. Sand filled buckets and closed cylinders are always kept ready to meet such accidents.

|